- Industries

- Solutions

- Products

- Our Company

- Knowledge

- Contact Us

Lean/Dilute Phase

Pneumatic Conveying Systems

Pneumatic Conveying Systems

Lean/Dilute Phase Pneumatic Conveying Systems

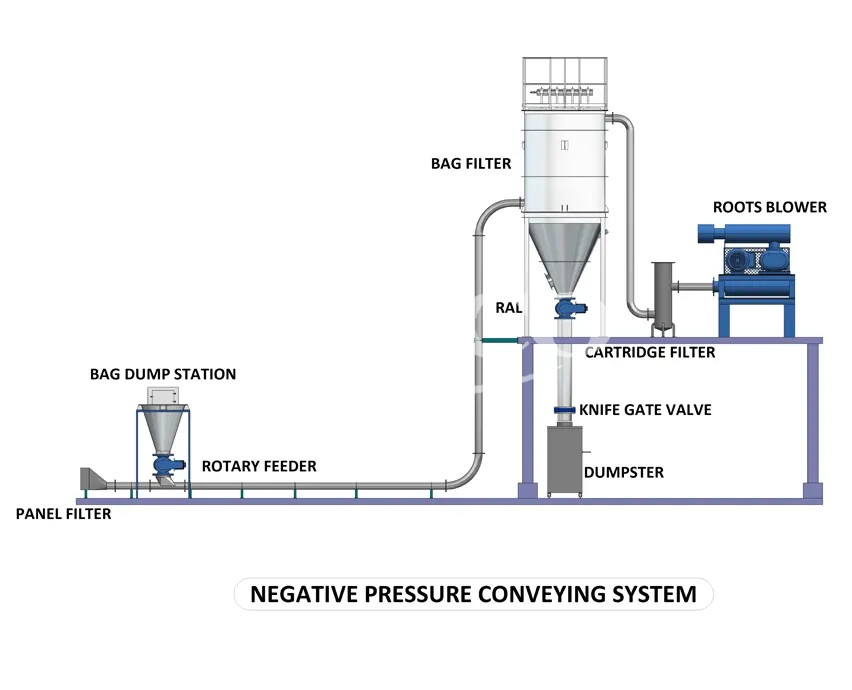

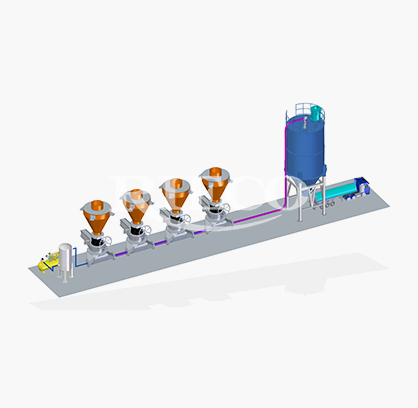

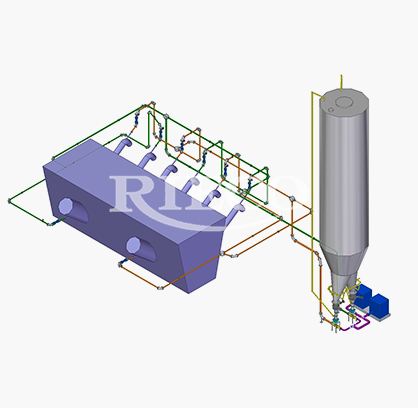

Our Our dilute pneumatic conveying systems function by utilizing low-pressure and high-velocity operations to transfer materials. This conveying technique is particularly effective for moving non-friable and non-abrasive materials that are suspended in air, utilizing a minimal material to air ratio.

With 47+ years of expertise, we have a broad range of installations in India and abroad, serving various applications across numerous industries. Our proven track record is a testament to the quality and efficiency of our pneumatic conveying systems.

X