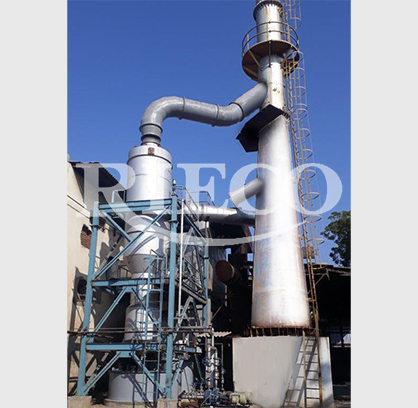

Multiclone

In the industrial processing, achieving efficient dust separation can be a significant challenge, especially when dealing with high-temperature dust-laden gas streams. Introducing Rieco's Multiclone dust collector – a cutting-edge solution designed to transform the way industries handle inlet and outlet particulate matter.

Multiclones are ingeniously designed with a series of small cyclones, also referred to as clones, equipped with specialized spinners in the casing. Operating on the principle of centrifugal force, they leverage the difference in specific gravity to isolate coarser particles from lighter gas streams. Multiclones act as robust pre-cleaners, ensuring an economically sustainable operation. The lack of moving parts not only guarantees an inexpensive construction but also a seamless and durable functionality.

Our multiclone dust collectors are the acknowledged air pollution control equipment, designed to meet various dust collection requirements. The multi clone technology offers precise particulate separation, ensuring comprehensive air pollution control. These multiclone dust collectors via a series of cyclones, separate particles from the gas stream, proving to be a cost-efficient solutions for cleaner environments.

How It Works?

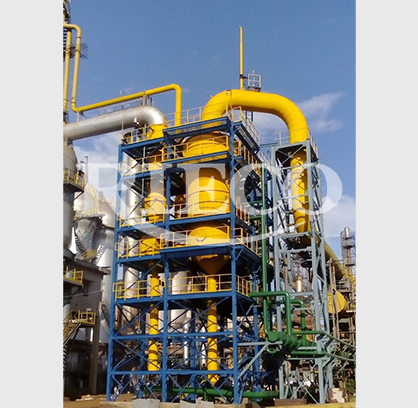

Multiclones consists of a housing with multiple collecting tube assemblies, each an individual centrifugal dust collector. Heavy dust laden gas enters from the top of the collecting multiclone tubes through the inlet guide channel vanes. These vanes give spiral action to the gases in a smooth way, resulting in a highly centrifugal action with less turbulence and minimal abrasion. As the gas travels down in a cyclonic direction, the dust is then forced due to centrifugal action away from the wall of the collecting tube and forces to the bottom where it is discharged through the dust discharge device. A strong vortex gets formed at the collecting tube bottom and the cleaned gases gets the whirl action on inner side causing travelling upward to clean air chamber.

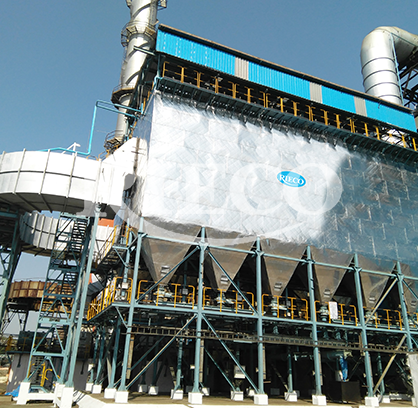

- Prolific Installation Record: We have numerous installations of multiclones in pallet & sinter plants, a testament to our product's reliability and efficiency.

- German-Designed Efficiency: With a German-designed and comprehensive data base of fractional efficiencies (particle sizes), we guarantee a Multiclone with top-tier separation efficiency.

- High Capacity Handling: We have successfully installed a Multiclone that handles an air volume of 3,00,000 Am3/hr at temperatures reaching 600°C in pallet plants.

- Unique Casted Design: Our exclusive casted design of the reversion cell & spinners ensures the highest efficiency and the lowest pressure drop.

- Special Alloy Casting: With a keen selection of special alloy casting tailored to specific applications, we guarantee the maximum lifespan for our spinners.

- Multiple Small Cyclones Design: Crafted with numerous clones, or small cyclones, to enhance dust separation efficiency.

- Specialized Spinners: Equipped with specialized spinners in the casing to optimize separation of coarser particles from gas streams.

- Centrifugal Force Principle: Operates by leveraging the centrifugal force to differentiate and separate particles based on their specific gravity.

- Durable Construction: Designed with no moving parts, ensuring long-lasting operation and minimal maintenance.

- High-Efficiency Pre-Cleaning: Acts as a robust pre-cleaner, making subsequent cleaning processes more effective.

- Unique Collecting Tube Assemblies: Each collecting tube works as an individual centrifugal dust collector for optimized separation.

- Guide Channel Vanes: Allows the dust-laden gas to enter and spiral smoothly, resulting in a highly centrifugal action with minimal abrasion.

- Effective Dust Discharge: Coarser particles are directed to the bottom and are efficiently discharged through the dust discharge device.

- Cleaned Gas Outlet: A strong vortex forms at the bottom, allowing the cleaned gases to move upward to the clean air chamber.

- Economically Sustainable: Due to its simplistic yet effective design, it offers a cost-effective solution for industries.

Why Rieco?

in your process challenges.

we are happy to answer