Gas Cleaning Plant (GCP)

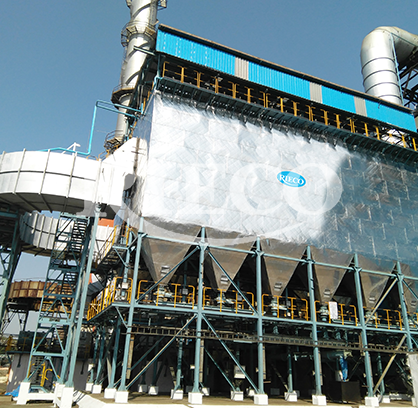

Our Gas Cleaning Plants are designed to treat gases from various industrial processes, including Mini Blast Furnaces. These plants efficiently process hazardous, calorically rich gases having high carbon monoxide content, reducing dust content to below 5 mg/Nm3. By converting these gases into a usable form for heating or other applications, RIECO's solution not only promotes environmental responsibility but also offers significant operational cost savings across different industries.

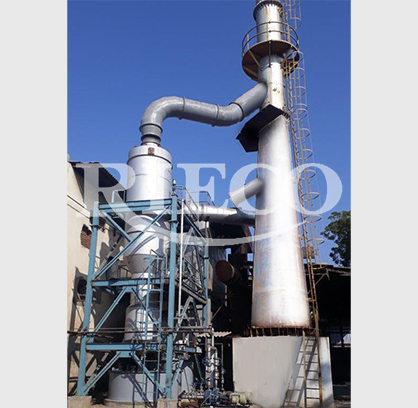

RIECO's Gas Cleaning Plant employs a two-stage High Energy Venturi Scrubbing system to clean dust-laden blast furnace gases. The first stage pre-cleans the gases, while the second provides thorough cleaning. Together, they efficiently remove 90-95% of dust particles using water recirculated from the Clarifier plant. Dusty water is then sent for treatment and recycling.

Gases from the first stage move to the second, encountering an adjustable venturi scrubber. Here, gas interacts with a water spray to separate fine dust. The adjustable venturi throat, responding to differential pressure, ensures optimal gas cleaning based on the furnace's output. Post-cleaning, gases pass through a Centrifugal separator, removing the finest water droplets. A specialized mist eliminator in the separator ensures the gas's moisture content is less than 5% before it's distributed for various applications.

Our expertise lies in designing, engineering, and supplying gas cleaning plants for both wet and dry applications. Key features and benefits of our GCP systems are as follows:

- Effective Cleaning: Reduces dust content in gas to below 5 mg/Nm3.

- High Efficiency Scrubbers: Uses double stage proven venturi technology.

- Adjustable Throat Design: Enables precise control on pressure drop across both venturi stages.

- Optimal Outlet Emission: Achieves emissions in the range of 5 to 10 mg/Nm3.

- Controlled Moisture Content: Ensures outlet gas moisture content is between 5 to 10%.

- Significant Pressure Reduction: Achieves a pressure drop of 3500 to 4500 mmWC across the GCP.

- Cost and Energy Efficiency: Offers low operational costs with reduced power consumption.

- High-Temperature Tolerance: Capable of handling high-temperature gases.

- Space-Efficient: Requires a minimal footprint for installation.

- Long-Term Benefits: Reduces the need for frequent downstream maintenance due to the GCP's efficiency.

- Minimal Inventory: Streamlined operations require less inventory management.

- Calorific Value Harnessing: Converts waste gas into valuable energy.

- Safety and Environmental Considerations: Designed for secure handling and eco-friendly operation.

- Reduced Maintenance: Built for durability and long-term efficiency.

With RIECO, you get a partner with proven industry experience, technological excellence, and a commitment to sustainable and efficient industrial operations.

Why Rieco?

in your process challenges.

we are happy to answer