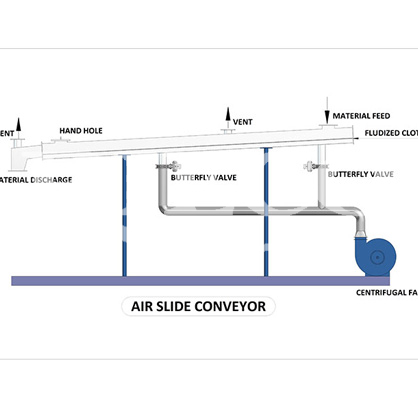

In Rieco's Air Slide, the principle of fluidised bed conveying is employed to transport bulk materials efficiently. Here's how it operates:

- Air is introduced into the system, creating a pneumatic gravity effect

- The bulk material is subjected to this air flow at a speed that surpasses the fluidising point's air velocity. As a result, the bulk material gets fluidised

- When fluidisation occurs within an inclined trough, the bulk material behaves like a fluid, seamlessly flowing down the trough's slope

- The mode of operation proves highly economical, particularly with fine-grained and dense powders

- The use of fans for generating the necessary air stream results in minimal energy consumption, making the system energy efficient

In essence, Rieco's Air Slide capitalizes on the fluidised bed conveying technique to transport bulk materials like liquid flow, ensuring both efficacy and economy in the process.