Air Classifyer

RIECO’s Air Classifier Mill (ACM) features integrated grinding, classification, conveying, and collecting operations. As a leading air classifier manufacturer, we ensure ultra-fine grinding (up to 2 microns*), depending on the product's nature.

Air classifying Mill / Air classifier Mill (ACM) can be designed for grinding hygroscopic, heat sensitive and explosive materials in inert gas/ closed loop systems with dry chilled air. Our classifiers are engineered to consistently produce steep particle size distributions that are uniform and homogeneous.

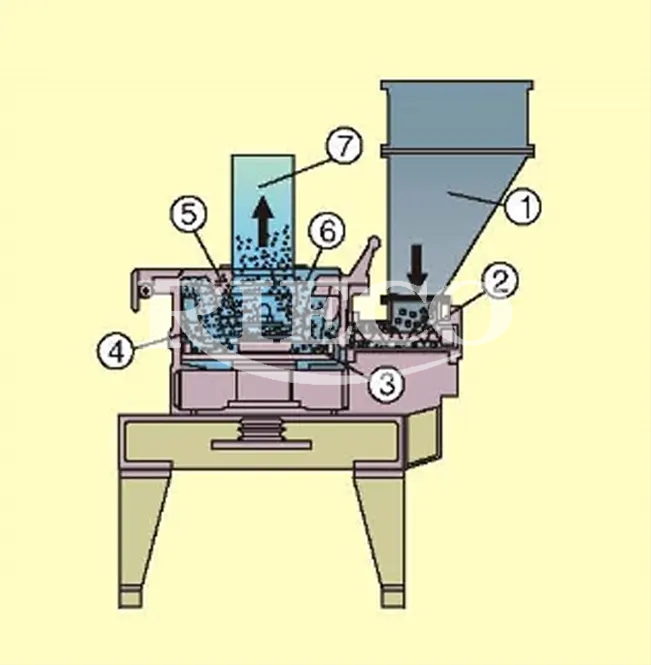

Working Principle

The material to be grinded is conveyed from the hopper to the grinding zone by the variable feed screw mechanism. The grinding occurs when the product meets a pin or bar-type rotor disc. As particles are reduced in size, they are entrained by the air stream, which enters below the rotor and is carried up between the inner wall and shroud ring with baffles. The particles are then deflected by an air dispersion ring to the separator assembly. As a leading air classifier manufacturer, we ensure that acceptable product is drawn through the exhaust and collected by a high-efficiency bag filter, while oversize particles are carried downward by the internal air classifier and returned to the rotor for additional grinding.

Technical Specifications

| Mill | Main Motor HP | Rotor RPM | Classifier Motor HP | Classifier RPM |

|---|---|---|---|---|

| ACM 5 | 5 | 9400 | 1 | 5400 |

| ACM 10 | 10 | 7000 | 1.5 | 5000 |

| ACM 30 | 30 | 4600 | 7.5 | 2500 |

| ACM 30 (ID) | 30 | 5000 | 7.5 | 3000 |

| ACM 60 | 60 | 3000 | 15 | 2000 |

| ACM 60(ID) | 60 | 3500 | 15 | 3000 |

| ACM 75(ID) | 75 | 3500 | 15 | 3000 |

| ACM 75(ID) | 75 | 3500 | 15 | 3000 |

| ACM 100 | 100 | 3000 | 15 | 2000 |

| ACM 100(ID) | 100 | 3500 | 15 | 3000 |

| ACM 5 | 5 | 9400 | 1 | 5400 |

| ACM 120 | 120 | 2200 | 20 | 1800 |

| ACM 150 | 150 | 2200 | 25 | 1800 |

| ACM 200 | 200 | 2200 | 40 | 1800 |

| ACM250 | 250 | 2200 | 40 | 1800 |

| ACM300 | 300 | 2200 | 50 | 1800 |

| ACM400 | 400 | 1500 | 100 | 400-1800 |

| ACM500 | 500 | 1500 | 125 | 400-1800 |

Features

- Modern, Economical, simple

- High Pressure Mills for dust explosive materials

- Closed Loop systems in inert atmosphere for explosive, heat sensitive and hygroscopic materials.

- Heat Exchanger based cool grinding system for non-explosive heat sensitive material.

- Grinding and Classifying in one machine with online granulation adjustment.

- Dust free Operation

- Uniform particle size distribution with narrow bandwidth.

- Mills can be provided with Online classifier (Micron separator) to further achieve sharp particle cut point

- Low specific energy requirement

- ACM variant with Independent Drive classifier wheel available for sticky materials.

- All RIECO ACM mills are equipped with protection devices for safe operation. These measures include a safety switch on the cover of the grinding chamber. It is thereby ensured that the drive motors cannot be switched ‘ON’ when the grinding chamber cover is open

- The plant is supplied along with a control panel and MCC which provides the necessary interlocks and operating switchess

- The mill and all drive components are mounted on a rigid welded stainless steel frame. All rotating parts are dynamically balanced for smooth operation. There is no need for special foundation.

Construction

As a leading air Classifier Manufacturer, we include the following in our ACM Plant:

- ACM Mill for grinding and classifying.

- High efficiency bag filter with automatic pulse jet cleaning

- Rotary Airlock (used for air seal and discharge material from bag filter)

- Centrifugal Fan (provide air flow through the mill and the collector for product conveying and cooling.)

- Control Panel (sequential starting and stopping of the milling plant)

Application

- Phenolic resins

- Toner Powders

- Talc

- PPT Silica

- Metal Stearates

- Modified Starch

- Turmeric

- Gluten

- Sugar

- Soya

- Ultrafine flour of pulses, grain

- Besan (gram flour)

- Lactose

- Pigments

- Dyes

- Colours

- Powder coatings

- Food Colour

- Active Pharmaceutical Ingredients

- Bulk Drugs

- Nutraceuticals

- Proteins

- Wettable pesticides

- Insectides

- Fungicides

- Herbicides

- Calcined clay

- Kaolin

- Wollastonite

- Ceramic Colours

Why Rieco?

in your process challenges.

Industries We Cater

we are happy to answer