Lean/Dilute Phase Pneumatic Conveying Systems

Our Lean pneumatic conveying systems function by utilizing low-pressure and high-velocity operations to transfer materials. This conveying technique is particularly effective for moving non-friable and non-abrasive materials that are suspended in air, utilizing a minimal material to air ratio.

Our Lean pneumatic conveying systems function by utilizing low-pressure and high-velocity operations to transfer materials. This conveying technique is particularly effective for moving non-friable and non-abrasive materials that are suspended in air, utilizing a minimal material to air ratio.

For low bulk density powders that have fine particulates and less air retention capabilities, we offer dilute mode conveying. In this mode, the material to air ratio is significantly low, thus ensuring the materials are conveyed in a state of suspension.

With 47+ years of expertise, we have a broad range of installations in India and abroad, serving various applications across numerous industries. Our proven track record is a testament to the quality and efficiency of our pneumatic conveying systems.

Types

There are two types of lean/dilute phase conveying systems-

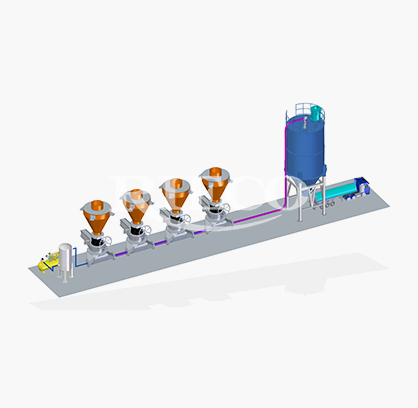

Positive Pressure Conveying System

Positive pressure systems operate above atmospheric pressure and are used to convey bulk materials over medium distances with greater capacity than using vacuum systems.

With diverter valves, multiple destination delivery one after the other reception points can be arranged easily with positive pressure systems.

Multiple feed points into a common line can also be provided ensuring proper selection and air quantity and special conveying Rotary air lock valves.

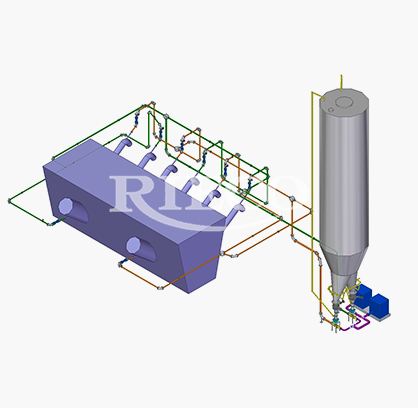

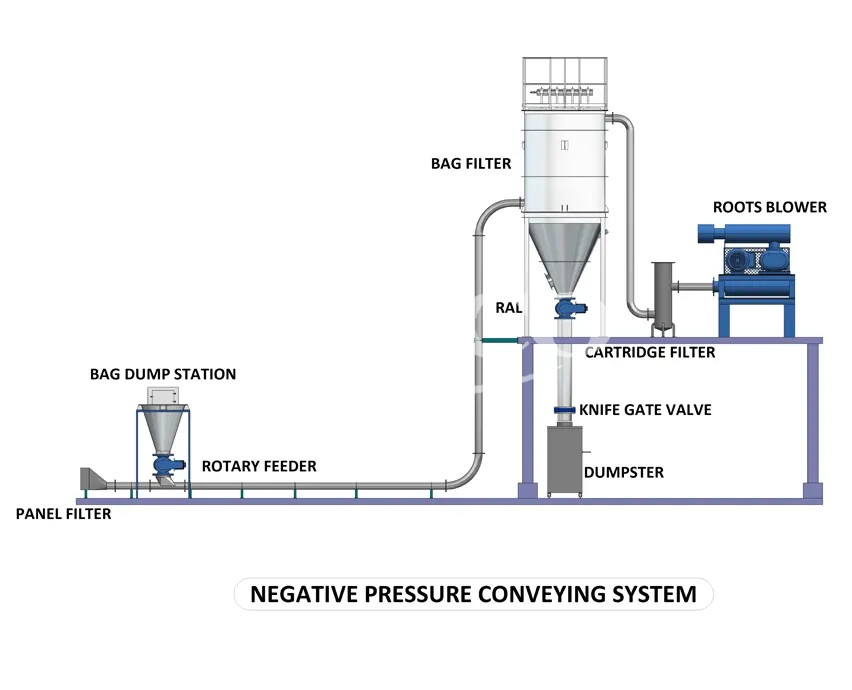

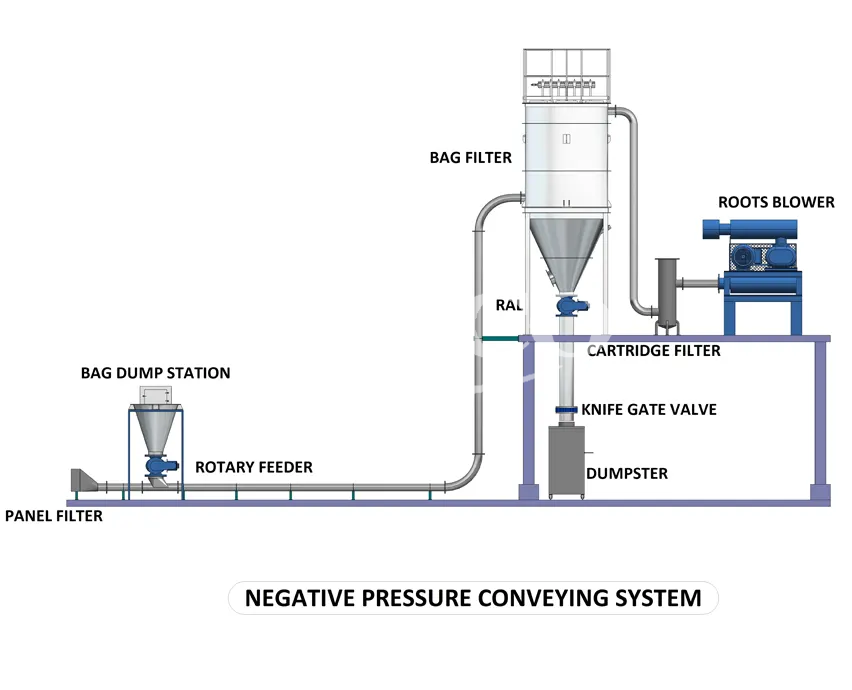

Vacuum/Suction/ Negative Pressure Conveying System

Negative pressure conveying systems operate with air pressures below atmospheric pressure.

A vacuum pressure is applied at the destination to suck the material from Rotary Airlock Valve (RAL)) or through suction tool and into the air stream.

With the advantage of gas leakage being inward, the dust injection into the atmosphere is virtually eliminated.

With the advantage of gas leakage being inward, the dust injection into the atmosphere is virtually eliminated.

Features

- Suitable for transferring wide range of materials for short distances

- Variety of particle size, shape or bulk densities can be conveyed

- Distribution to multiple areas in a plant and pick-up from several points

- Dust free operation, less spillage resulting in good yield recovery

- Flexibility in routing – can be transported vertically and horizontally by the addition of a bend in the pipeline

- Atomized powder handing ensuring better process controls, less manpower, safety in Plants Total hygiene is maintained due to less exposure of manhandling

- Lime

- Hydrated Alumina

- Calcium Carbonate

- Pulverized coal dust

- Brown friction Powder

- Hexamine

- Red and Blue Pigments

- Soap noodles

- PPT Silica

- Horlics and Boost

- Ammonium Nitrate

- Grinded Fly ash

- Pharmaceutical Powders

- PVC Powder

- Green Powder

- Wheat

- Sugar

- Maida

- Soya flakes

- Polystyrene Beads

- Dental grade Silica Powder

- NDC powder, Coffee beans

- Mona Penta enthral powder

- Gluten Powder

- Soya Flour

- Spent Wash Powder

- Starch

- Naptcol

- Zinc powdered

- Dyes & Pigments

- Titanium Dioxide/TiO2

- Dyes

- Black oxide

- Paracetamol powder

- Chlorine powder

- Carbon Chips

- Dry Ginger Cummins

- Kiln ESP Dust

- Isoproturon Powder

- Black oxide

- Urea

- Lime Powder

- Phthalic anhydride

- Polyester chips

- PET chips

- HDPE

- polyethylene

- Carbon Black

- CPVC and UPVC

- Dyes and Pigments

- Black Paper

- ABS Powder

- Mancozeb

- Mica

- Dry Gelatine Granules

- Marigold flowers

- …many more

Why Rieco?

in your process challenges.

we are happy to answer