Dry Sorbent/Lime Injection System

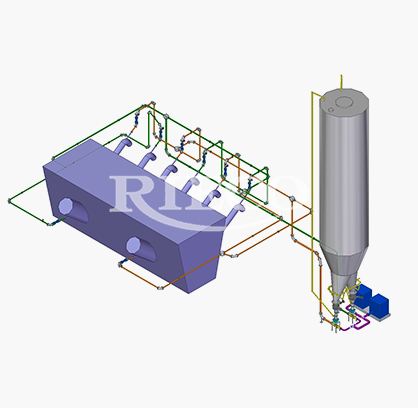

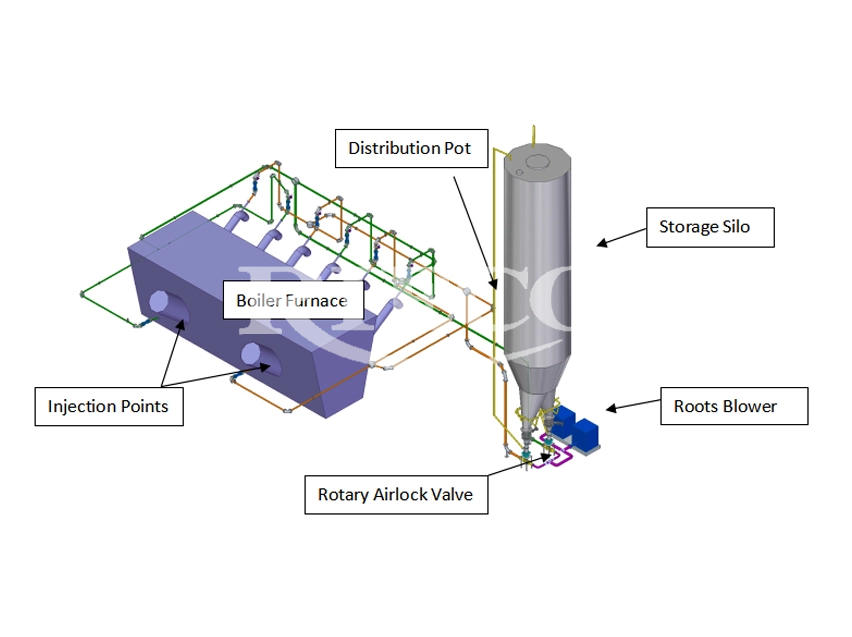

Dry Sorbent Injection is a technology used for air pollution control in various industrial processes, particularly in power plants. This method involves dry sorbent, typically a hydrated lime or sodium bicarbonate-based compound, directly injected into the flue gas, to prevent the effects of acid gas and other high-risk pollutants. The sorbent then reacts with and neutralizes certain pollutants, particularly acid gases such as sulfur dioxide (SO2), hydrogen chloride (HCl), or other air pollutants, effectively reducing their particulate matter in the emissions.

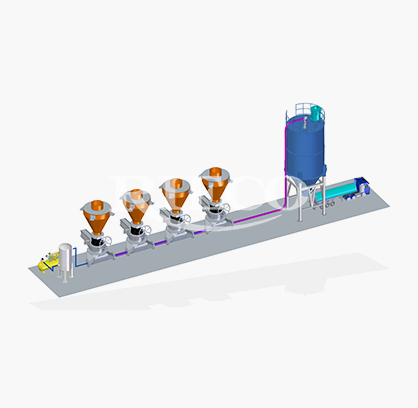

Our Dry Sorbent Injection (DSI) System combines the benefits of dry sorbent injection with the efficiency and reliability of pneumatic conveying, ensuring optimal performance in industrial applications. By injecting a dry lime-based sorbent directly into the flue gas stream, our system facilitates rapid and thorough pollutant neutralization and removal. The advanced pneumatic conveying technology at the core of our system allows for precise and controlled sorbent injection, ensuring uniform distribution and maximum contact with the pollutants. We ensure enhanced environmental compliance, reliability, and a cleaner, safer environment.

Features

- Effective Pollution Control: DSI systems reduce harmful pollutants like sulfur dioxide (SO2), hydrogen chloride (HCl), and other hazardous air pollutants in flue gas streams.

- Cost-Efficient: Compared to other air pollution control technologies, DSI systems are generally more affordable to install and operate.

- Simple Implementation: DSI systems are straightforward to integrate into existing processes, requiring fewer modifications and less downtime for installation.

- Flexibility: They can be used across a wide variety of industrial applications and can handle a range of pollutants.

- Enhanced Safety: By reducing harmful pollutants, DSI systems contribute to safer work environments and help businesses comply with environmental regulations

- Low Maintenance: DSI systems are designed for durability and require relatively little maintenance, contributing to their cost-effectiveness.

- Adaptable Performance: The amount of sorbent injected can be adjusted based on the specific requirements of each application, allowing for flexible and efficient operation.

- Minimal Waste: DSI systems produce less waste than wet systems since they do not require water for operation.

Dry sorbent injection systems can be seamlessly integrated with fabric filters and electrostatic precipitators, effectively cutting down the pollution. While these sorbent injections contribute to reduced emissions and operating costs, they are recommended for industries looking for affordable air quality management.

Why Rieco?

in your process challenges.

we are happy to answer