Air Slide

Rieco's Air Slide offers a streamlined and efficient method for conveying bulk powder materials across industries. Using a simple design that combines low-pressure air, an aeration bed, and an inclined channel, the system ensures seamless transportation of homogenous dry powders. With minimal parts and energy usage, Rieco's Air Slide is not only reliable and continuous, but also cost-effective and eco-friendly.

Operation of Rieco's Air Slide: Fluidised Bed Conveying

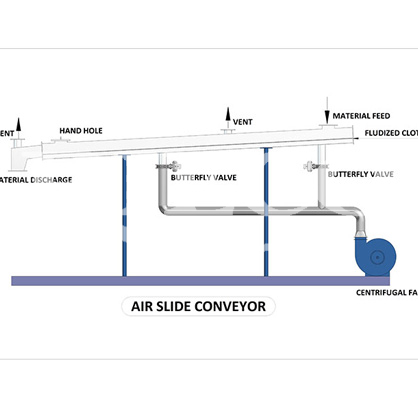

In Rieco's Air Slide, the principle of fluidised bed conveying is employed to transport bulk materials efficiently. Here's how it operates:

- Pneumatic Gravity Conveying: Air is introduced into the system, creating a pneumatic gravity effect.

- Fluidisation: The bulk material is subjected to this air flow at a speed that surpasses the fluidising point's air velocity. As a result, the bulk material gets fluidised.

- Flow Through an Inclined Trough: When fluidisation occurs within an inclined trough, the bulk material behaves similarly to a fluid, seamlessly flowing down the trough's slope.

- Trough Gradient: The inclination or gradient of the trough is crucial for facilitating the movement of bulk material. The precise gradient and resulting product flow rates are contingent upon the specific material being conveyed.

- Economic Operation: This mode of operation proves highly economical, particularly with fine-grained and dense powders.

- Air Production and Energy Efficiency: The use of fans for generating the necessary air stream results in minimal energy consumption, making the system energy-efficient.

In essence, Rieco's Air Slide capitalizes on the fluidised bed conveying technique to transport bulk materials in a manner akin to liquid flow, ensuring both efficacy and economy in the process.

Features

- Efficient Fluidisation Technology: Employs pneumatic gravity conveying that fluidises bulk material, allowing it to flow like a liquid.

- Continuous Conveying: Operates without interruption, ensuring a steady and dependable flow of materials.

- No Moving Parts: The absence of mechanical components results in significantly reduced wear and tear.

- Less Maintenance: Simplicity of design means lower maintenance requirements, saving time and resources.

- High Throughput: Capable of handling a substantial volume of materials, making it ideal for high-capacity operations.

- Low Cost: Economical operation, particularly when compared with many traditional conveying systems.

- Low Energy Requirements: Utilizes fans for air production, resulting in minimal energy consumption and cost savings.

- Environmentally Friendly: Low energy consumption and the absence of dust emissions make it a green choice for material handling.

- Inclined Flow Troughs: Customizable inclinations of the troughs, based on material properties, ensuring effective and controlled material flow.

- Wide Range of Applications: Versatile system that can be employed across various industries, including cement, chemical, metallurgical, and food sectors.

- Space Saving Design: The air slide's compact and flat design allows for easy installation in constrained spaces.

- Safe Operation: Low risk of blockages and explosions, and it operates quietly, contributing to a safer workplace environment.

- Scalable and Modular: Can be easily scaled up or down and integrated into existing systems as per the requirement.

- Precise Control: Allows for accurate control of flow rates through adjustments in air pressure and volume.

Why Rieco?

As your global partner, we fully immerse ourselves

in your process challenges.

in your process challenges.

48 +

Years of Experience

40 +

Countries

6000 +

Successful Installations

300 +

Strong Team

5 +

Global Partnerships

3

Manufacturing Facilities

Industries We Cater

Global Presence

We’re there for you

Feel free to ask us anything you have in mind,

we are happy to answer

we are happy to answer

Enquire Now

Close

Enquire Now