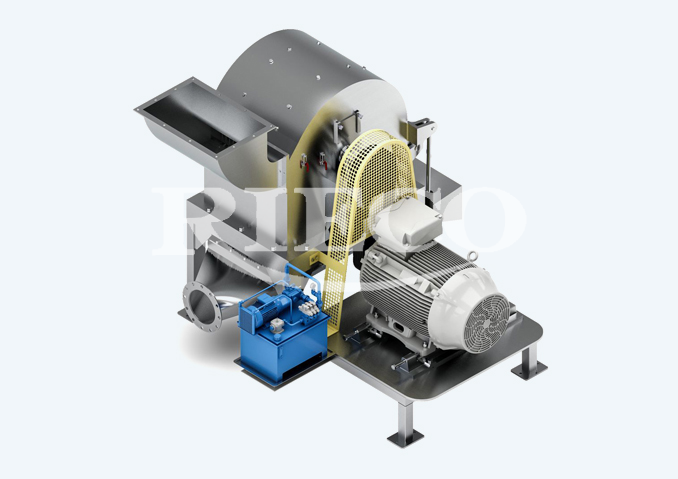

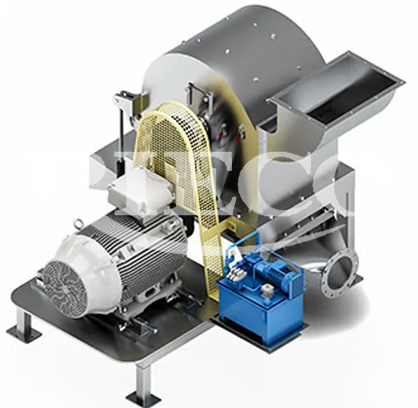

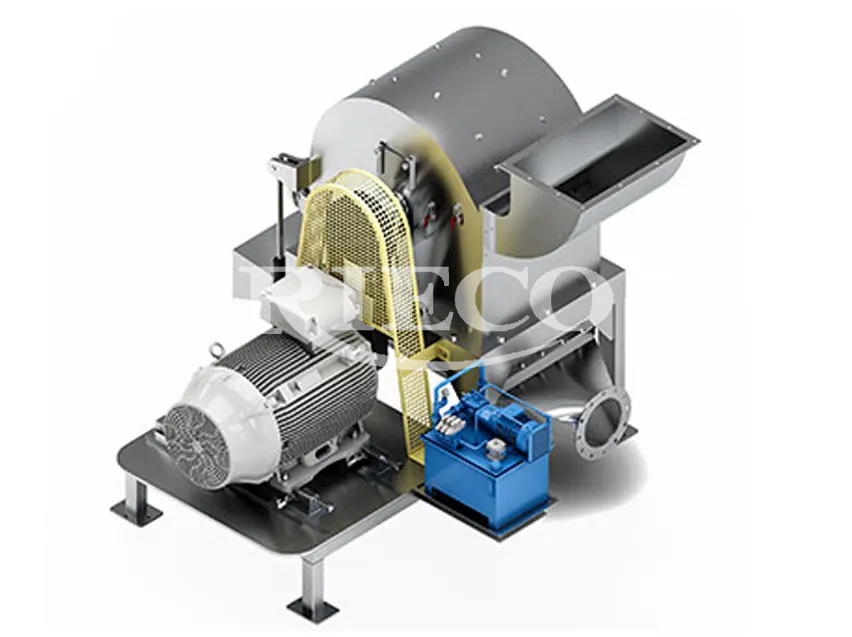

Pulvionex 200 (TM)

Introducing the Pulvionex 200TM: a cutting-edge, heavy-duty hammer mill with a resilient design. With its Staggered Rotor Design, optimized hammers, and aerodynamics, it ensures stability, reduced vibrations, and easy cleaning. The mill guarantees size reduction to D90 of 20-40 BSS mesh, adheres to food hygiene standards, and features wear-resistant alloy parts. Its diverse hammer profiles promise high-capacity grinding and superior yield. The hydraulic mechanism allows easy door access for swift maintenance, making it suitable for grinding chilli, spices, herbs, grains, pulses, and soft minerals. Experience unmatched grinding performance with its 150 HP power and long-lasting durability. Choose Pulvionex 200TM, a heavy duty universal milling machine for innovation, efficiency, and reliability.

Features

- An Ingenious Staggered Rotor Design

- Meticulously optimized heavy duty hammer mill

- Adherence to aerodynamic principles

- Exceptional stability, minimal vibrations, and effortless cleaning

- Large screen area and segmented liner for efficient grinding

- Improved cooling design for enhanced operation

- Economical grinding for cost-effective production

- Reduced vibration for smoother operation

- Hydraulic door opening arrangement provides a seamless and convenient solution for easy access.

- Easy screen and liner changes for convenient maintenance

- Its robust construction ensures supreme performance and durability.

- All rotating parts are covered by the perforated guard which ensure human safety and reduces noise levels.

- All rotating parts are dynamically balanced for smooth operation.

- Optimum machine casing thickness ensures human safety.

- Automatic door opening arrangement without human interference.

- The milling machine and all drive components are mounted on a rigid welded steel frame.

- Machine base frame is designed with the smooth edges and optimum ground clearance to ensure safety with the best machine performance.

- Available in MS/SS/Carbon Steel

Why Rieco?

in your process challenges.

Industries We Cater

we are happy to answer