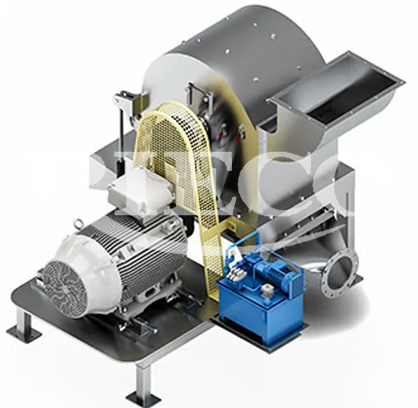

Micro Pulveriser

Our Mikro Pulveriser is a robust and efficient grinding unit for economically grinding a wide range of products. Benefit from exact particle size control, ensuring high production rates. With an adaptable design, it easily processes diverse materials and boasts an output capacity ranging from 20 to 4000 kg/hr. Whether you need a standalone unit or one that's seamlessly integrated with a dust-free extraction and containment system, we've got you covered. Dive into a world of dependable efficiency, superior productivity, and economic solutions with our Mikro Pulveriser —perfect for individual operations as well as incorporation into your existing infrastructure. We offer diverse equipment, whether pulveriser hammer screen mills or mixer ribbon blenders as a trusted manufacturer exporter. To know more in detail, go through our product brochure.

Construction and Range

Construction -

- RIECO’s Mikro-Pulveriser Machine consist of essential components for optimal grinding performance

- Rotor assembly with high-speed operating hammers

- Housing with a diversity of multi deflector or plain liner.

- Retaining screen at the mill discharge point

- Feed screw mechanism for uniform material feeding into the grinding machine.

- The grinding process relies on the impact between rapidly moving hammers and particles on the liner.

- This impact-driven working principle ensures efficient reduction of particle size.

- RIECO's Mikro-Pulverisers are designed with meticulous precision to achieve consistent and precise grinding results.

- Each component is engineered to maximize performance and achieve the desired particle size distribution in the wide range of materials processed by the pulveriser machine.

Design -

Depending on the specific application, each model is available in various configurations, encompassing diverse design aspects such as construction materials, wear protection, and feed metering element, ensuring efficient performance for a flour mill or ss pulviser.

- Pulveriser SH, DH or TH: These models facilitate material feeding through one, two, or three metering screws, employing single trench, twin trench, or triple trench mechanisms.

- Pulveriser W: This model enables gravity feed, catering to suitable products and their requirements in the stainless steel construction.

- Pulveriser SCB (Special Carbon Black): Specifically designed for grinding carbon black highly abrasive material, this variant features a suction inlet or injector, tailored to meet the unique demands of carbon black processing.

Range -

| Micro Pulveriser | HP Range |

|---|---|

| 1W | 5-7.5 |

| 1 SH 2W |

5-7.5 10-20 |

| 2 DH / 2 SCB 3W 3 TH / 3 SCB |

10-20 30 - 50 30 - 50 |

| 4W | 75 - 100 |

| 4 TH / 4 SCB | 75 - 100 |

Features

- Meticulously optimized hammers

- Available production models, ranging from 5 HP to 100 HP.

- Capacities spanning from 20 Kg/hr to 4000 Kg/hr.

- Exceptional stability, minimal vibrations, and effortless cleaning

- Available in GMP grade for specialized needs.

- Custom pulverisers for Carbon Black use.

- Choice of water-cooled or air-cooled bearings for high-heat tasks.

- All rotating parts are dynamically balanced for smooth operation.

- Automatic door opening arrangement without human interference.

- Available in MS/SS/Carbon Steel

Why Rieco?

in your process challenges.

Industries We Cater

we are happy to answer