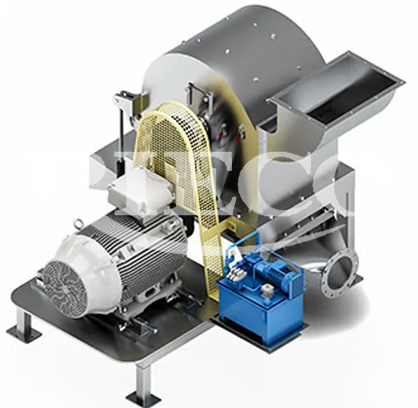

Hammer Mill

RIECO's Hammer Mill is your ideal solution for precision grinding, sieving, and collection of various materials. Ingeniously designed to grind a vast range of non-hygroscopic, non-heat sensitive, and non-explosive materials, our Hammer Mill ensures consistent small particles size reduction. Owing to its high speed rotating shaft in the grinding chamber, it effectively grind materials. The steel hammer comes with with the provision for collection of the material at the bottom gravity through steel drum or pulsaire jet product collector with dust free operation and providing customized capacity variants. This milling machine is the transformative answer to your heavy duty grinding needs.

Technical Specifications

We have following types of hammer mill available used for wide variety of applications including;

| Mill | HP Range |

|---|---|

| 1W | 3-7.5 |

| 2W | 10-20 |

| 3W | 30-50 |

| 4W | 60-100 |

| HM-03 | 7.5-10 |

| HM-24 | 20-40 |

| HM-32 | 50-100 |

| HM-36 | 60-100 |

Features

- Hydraulic Door System: Facilitates easy access with a seamless, fully automatic door opening arrangement.

- Energy Efficiency: Engineered to consume minimal power, reducing operational costs, and promoting sustainable practices.

- Unique Beaters Design: Hammers/Beaters are designed for the best performance.

- Powerful Grinding Capabilities: Consistent and precise particle size outcomes.

- Customizability: Tailor the grinding process to specific requirements from 20kg/h to 5000kg/h.

- Fineness of Product: It can grind any material up to 45-75 micron depending upon the physical & chemical properties of the product.

- Material Options: Available in both MS (Mild Steel) and SS (Stainless Steel) 304/316, with added wear protection.

Construction

- External Control Feed: Streamlined feeding process for enhanced efficiency.

- High-Efficiency Bag Filter: Fully automatic pulse jet cleaning ensures dust-free operation.

- Rotary Airlock: Acts as an air seal and aids in discharging material from the bag filter.

- Integrated Fan: Facilitates airflow through the mill and collector, enabling efficient product conveying.

- Control Panel: Offers sequential starting and stopping for the milling process.

Why Rieco?

in your process challenges.

Industries We Cater

we are happy to answer