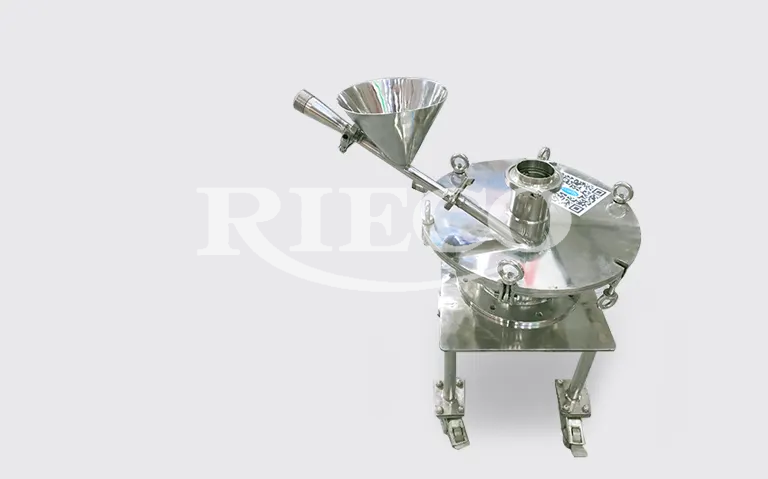

Air Jet Mill

Air jet Mill is shearing action grinding and collecting operations for achieving ultra-fine grinding upto 0.4 micron to 15 microns* depending upon the nature (Physical & Chemical Property) of the product. Air jet mill (also known as micronizer) is designed for grinding hygroscopic, heat sensitive and explosive materials to achieve consistent steep particle size distribution. Air Jet Mill allows greater control over the grinding parameters and product particle size distribution.

Technical Specifications

| SPIRO Standard Series | ||||||||

|---|---|---|---|---|---|---|---|---|

| Diameter (inches) | 4 | 8 | 12 | 16 | 20 | 24 | 30 | 36 |

| Capacity (kg/hr) | 0.3-10 | 5.0-40.0 | 20-100 | 60-150 | 90-200 | 120-350 | 180-500 | 350-700 |

| Max grind air flow (m3/hr) | 75 | 225 | 455 | 600 | 770 | 1360 | 1775 | 2345 |

Operation of Rieco's Roasters

- The Powder Particles are accelerated in spiral movement inside the milling chamber by number of angular holes in a ring and placed around the periphery of the chamber. Air jet Mill easily micronizes the heat sensitive and low melting point materials

- Rieco’s Jet mills do not have any moving parts, thus the chances of contamination due to contact with grinding media is eliminated. It’s an ideal process to grind material that are heat- sensitive and sticky as no additional heat is generated. It works solely on fluid energy

Features

- No Contamination and No Heat Generation

- Easy cleaning and Maintenance

- Extreme fine powder output, more uniform & more efficient

- Most suitable for 1 micron to 15 micron particle size

- Optimal air consumption depending on the size of the mill

- Improves solubility, dissolution & Bio availability

- Dust free Operation

Why Rieco?

As your global partner, we fully immerse ourselves

in your process challenges.

in your process challenges.

48 +

Years of Experience

40 +

Countries

6000 +

Successful Installations

300 +

Strong Team

5 +

Global Partnerships

3

Manufacturing Facilities

Industries We Cater

Global Presence

We’re there for you

Feel free to ask us anything you have in mind,

we are happy to answer

we are happy to answer

Enquire Now

Close

Enquire Now