- Industries

- Solutions

- Products

- Our Company

- Knowledge

- Contact Us

Lean Phase Pneumatic Conveying System for Minerals

Industry:

Mining and Mineral Processing

Client:

India’s leading Miner and Producer of wollastonite, Calcium Carbonate etc.

Location:

Udaipur, Rajasthan

Application :

Two stage Pneumatic Conveying for Calcium Carbonate Powder

Client requirement –

- Get feed from the Grinding will through Screw Conveyor and Pneumatically Convey it to Storage Silos.

- Further Convey it to End User’s Storage silo by means of Pneumatic Conveying

- Material transferred to client’s customer, which is beside to the client's factory

Challenges

- Ensuring less to no leakage of the material in the environment

- Metered quantity of material to be conveyed through pneumatic conveying system

- Long distance conveying through lean/dilute phase pneumatic conveying system

- Material to be conveyed in the closed pipe since the powder is hygroscopic in nature

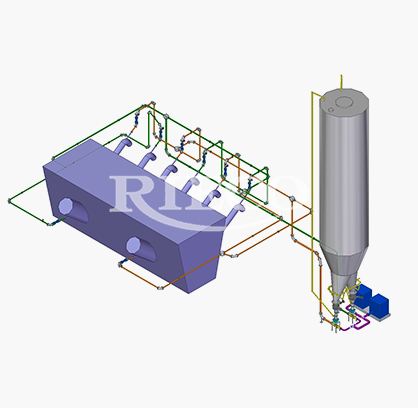

2nd Stage of Pneumatic Conveying System

- Two conveying lines, one for present use and second for future expansion

- 2nd stage get feed from Storage silos of 1st stage and deliver it to storage silos of end user

Solution

Rieco has offered Lean Phase Positive Pneumatic Conveying System to cater to this requirement.

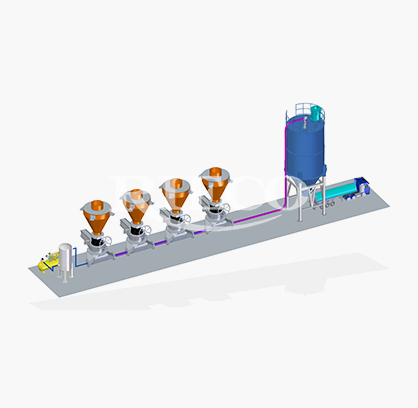

- The system has been designed in Two stages, 1st stage get feed from Screw Conveyor located below Cyclone Separator which get feed from Grinding Mill

- From there material gets stored in Surge Hopper from where it flows to Conveying Pipe through Rotary Airlock Valve

- Series of Pneumatically Operated Diverter Valve and Dome Valves are in place to direct the flow of material to Desired Silo

- Each Silo is fitted with Vent Filter, Level Sensor, Breather Valve & Bin Activator

- Each silo is fitted with load cells to calculate mass of incoming and outgoing material

- Diverter valve is provided at outlet of silos which can direct the material to Loading bellow or to second stage of conveying system

- 2ND Stage is comes with two sets of Pneumatic conveying lines and Prime Movers; One for present application and second for future expansion

- In 2ND stage of system material feed into vent filter and goes into Pneumatic conveying line through Rotary Airlock Valve

- Series of Pneumatically Operated Diverter Valve and Emod Valves are in place to direct the flow of material to Desired Silo

Why Pneumatic Conveying System ?

- Best suited for long distance conveying

- Low maintenance as compared to mechanical conveying

- Clean and dust free operation.

- Flexibility in routing – can be transported vertically and horizontally by the addition of a bend in the pipeline

- Automatic powder handing operation ensuring better process controls, less manpower, safety in plants

- Feed Moisture -10- 16 %