Wet Scrubber

With over 200+ global installations, our scrubbers are tailored to tackle diverse industrial needs, from Flue-gas Desulphurization to Gas Cleaning Plants. As a wet scrubber manufacturer in India, RIECO offers advanced solutions for air pollution control systems. Whether you need Wet Scrubbers using liquid solutions via mist eliminators or Dry Scrubbers employing reagents for acid gases, we have the expertise and technology to ensure optimal efficiency.

Understanding the nuances of particle distribution and droplet size, we're dedicated to providing the best in air purification solutions. Choose RIECO – a trusted wet scrubber manufacturer in India – for cleaner air and unparalleled reliability. All our wet scrubbers comply with environmental regulations and maintain air quality standards in industrial settings.

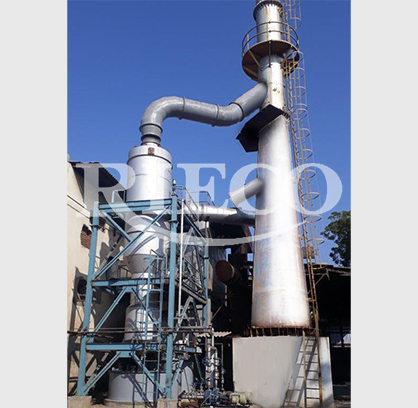

A Venturi Scrubber is an air pollution control device that uses a combination of fluid mechanics and particle dynamics to remove particulate matter from exhaust gas streams. The gas stream is accelerated through a constricted section (Venturi throat), causing turbulence. As the gas speed increases, liquid is introduced, creating fine droplets that interact with and capture particulates due to the increased turbulence. RIECO scrubber systems, with these overarching features, are a testament to our commitment to innovation, efficiency, and environmental responsibility in the realm of industrial air pollution control.

Types of Scrubbers

A Venturi Scrubber is an air pollution control device that uses a combination of fluid mechanics and particle dynamics to remove particulate matter from gas streams.

-

Mechanism :

- The gas stream is accelerated through a constricted section (Venturi throat) causing turbulence. As the gas speed increases, liquid is introduced, creating fine droplets that interact with and capture the particulates due to the increased turbulence.

-

Features :

- High particle collection efficiency

- Ability to handle variable gas streams

- Effective for very fine particles

-

Applications :

- Gas cleaning plants of mini blast furnace in steel industry

- Industries producing dust and fly ash like power plants

- Chemical and acid manufacturing processes

- Metal processing industries

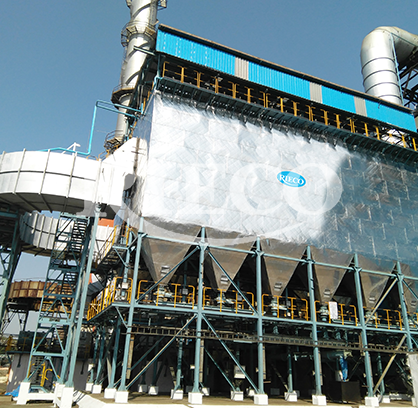

A Centri- Scrub removes particulates from gas streams by passing the gas through a film of liquid formed over a vane assembly.

-

Mechanism :

- Gas is introduced from the bottom of the centriscrub tower and the liquid flows from the top forming a film between the vanes of vane assembly. The particles are captured by the liquid as the gas passes through.

-

Features :

- Compact design

- Handles coarse dust loads

- Low pressure drop design

- Low maintenance requirements

-

Applications :

- Dust-intensive industries such as woodworking and cement production

- Boilers and furnace exhaust

- Agricultural processing facilities

- Dedusting systems for coal handling plants

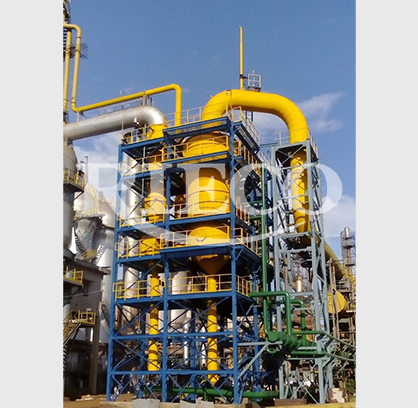

This is a combination of a spray tower along with pipe deck assemblies and is suited for gas absorption using dense recirculation slurries.

-

Features :

- Medium pressure drop system

- Can handle concentrated lime, limestone slurry for SO2 removal systems

-

Applications :

- Wet FGDs based on lime and limestone

This scrubber comprises of row of pipes laid adjacent to each other forming venturi like profile in the space between two pipes.

In this type of scrubbing, liquid and gas enter the scrubber in a cocurrent manner and mass transfer from gas to liquid takes place owing to the turbulence formed between adjacent pipes forming venturi like profile.

-

Features :

- This design is suited for low dust loads and offers a low pressure drop.

- A typical unit may include 2 or 3 decks of pipes one above the other. Multiple capture stages for improved efficiency

- Reduced liquid usage

-

Applications :

- Situations requiring high-efficiency particle removal

- Pollution control in chemical processing plants

- Industrial processes generating fumes and mists

A Dynamic/Wet Fan Scrubber, designed by a leading wet scrubber manufacturer in India, is a device that integrates a fan within the scrubbing process, facilitating better interaction between the gas stream and scrubbing liquid.

-

Mechanism :

- The in-built fan increases turbulence in the gas stream, aiding the scrubbing liquid in capturing pollutants more effectively.

-

Features :

- Enhanced particle capture due to increased turbulence

- Reduced system complexity and footprint

- Adaptability to varying flow rates

-

Applications :

- Better suited for sticky and abrasive dust

- Pelletizing plant in steel industry

- Ventilation and exhaust systems

- Food processing plants

- Chemical manufacturing facilities

The Packed Bed Scrubber is a type of scrubber designed with layers of packing materials to maximize the contact between the gas stream and the scrubbing liquid.

-

Mechanism :

- Gas passes through beds of packing material, increasing its interaction with the scrubbing liquid. This enhanced contact ensures efficient removal of soluble gases and particulates.

-

Features :

- High removal efficiency for gaseous pollutants

- Scalable for large volume applications

- Ability to handle a variety of pollutants

-

Applications :

- Flue gas desulphurization systems

- Not suited for handling dust bearing gases

- Waste treatment facilities

- Chemical and petrochemical plants

- Acid manufacturing and other processes releasing gaseous pollutants With the distinct features and mechanisms of each scrubber type, Rieco ensures that businesses have the most suitable solution for their unique air pollution control needs.

- High Efficiency: Designed to offer optimal removal rates of both particulate matter and gaseous pollutants across various scrubber types.

- Integrated Systems: Scrubbers can be seamlessly integrated with existing systems, allowing for a streamlined and efficient operational flow.

- Energy-Efficient: Designed to perform at peak levels while minimizing energy consumption, ensuring cost-effective operation

- Suitable for high temperature applications.

- Customizability: Flexible designs allow for customization to fit specific industrial requirements and regulatory standards.

- Compact Design Options: Many scrubber types, especially dry scrubbers, are space-efficient, making them ideal for industries with space constraints.

- Robust Construction: Built to withstand diverse industrial conditions, ensuring longevity and durability

- Environmentally Friendly: Engineered with sustainability in mind, they ensure minimal environmental impact by effectively reducing emissions

Rieco scrubbers, with these overarching features, are a testament of our commitment to innovation, efficiency, and environmental responsibility in the realm of industrial air pollution control.

- Acid Mist

- Furnaces

- Autoclaves

- Gas absorption

- Building product mfg

- Incinators

- Blow tanks

- Kilns

- Boilers

- Lime hydrators/slakers

- Conveyors and transfer points

- Odor Control/removal

- Cupolas

- Crushers and screens

- Palletizing dissolving tank

- Vents rendering

- Dryers

- Sand systems

- Fumes/VOC smelters

Why Rieco?

in your process challenges.

we are happy to answer