Explosion Protection Devices

Safety is paramount in industrial operations, particularly protection against explosions and fire, which pose severe risks to lives and assets. This danger arises when explosive substances, oxidizing agents, and an ignition source are present at the same location and time. To combat these risks, RIECO has partnered with RSBP, a Czech company since 1992, to provide comprehensive Explosion and Fire Protection solutions. We cover everything from concept and design to delivery and installation, adhering to all relevant safety standards and regulations, including ATEX, VDI, and NFPA. Our tested products and tailored services meet the current legislature requirements, ensuring the utmost safety of people and facilities.

Explosion Protection Solutions

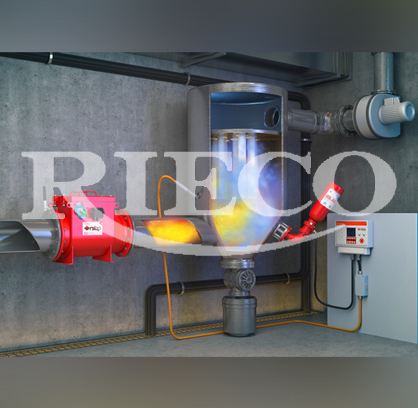

Explosion Suppression

HRD (high rate discharge) system is a well-tried system for explosion suppression. It detects the initial phase of the explosion and then suppresses explosions of flammable dust in industrial technologies. The equipment reaction time counts in milliseconds. Thanks to its perfect function the HRD system effectively suppresses explosion, limits explosion pressure inside equipment under its pressure resistance, and thus prevents its destruction. It eliminates technological damages, but primarily protects human health.

Explosion Venting

As an option to spring-loaded doors, rupture disc or explosion vents are used in the industry for the protection of the equipment from high-pressure explosion waves. Rupture discs/explosion vents are designed at certain low bust pressure against the equipment designed pressure. At the time of the explosion, these vents/discs provide an easy opening at the bust pressure allowing combustion gases to escape. These are one-time used devices & replacement is required only once it breaks out.

FLEX flameless explosion venting

For the gases coming from certain application gas stream which is explosive in nature, it is recommended for the explosion protection provided before the gas i.e. isolating the system & break the explosive gas stream. This flame-front device is majorly used on the coal mill application Baghouses & also is termed as a cage vent. The device is designed in such a way that it changes the direction of the explosive gases flows to 180 o resulting in venting out of the gases to the atmosphere by the opening of the rupture disc at the top. The special protection viz. cage is provided to avoid the fly out of the rupture disc into the atmosphere. This ensures the hot explosive gases are relieved out into the atmosphere in a safe area. This design does not elude any explosion, but it distracts the explosion & low-intensity explosion takes place in the downstream equipment.

Explosion isolation

Explosion isolation system includes a mechanical device designed to prevent the propagation of flame and pressure between pieces of technology equipment during the explosion. It's a system that protects technologies intended for operation in an explosion danger environment. B-FLAP I is a mechanical device designed to prevent the propagation of flame and pressure between pieces of technology equipment during an explosion. B-FLAP I is, together with other safety measures, a part of a system that protects technologies intended for operation in an explosion danger environment. The economical solution of protection against propagation of explosion between pieces of technology equipment is the B-FLAP I back flap.

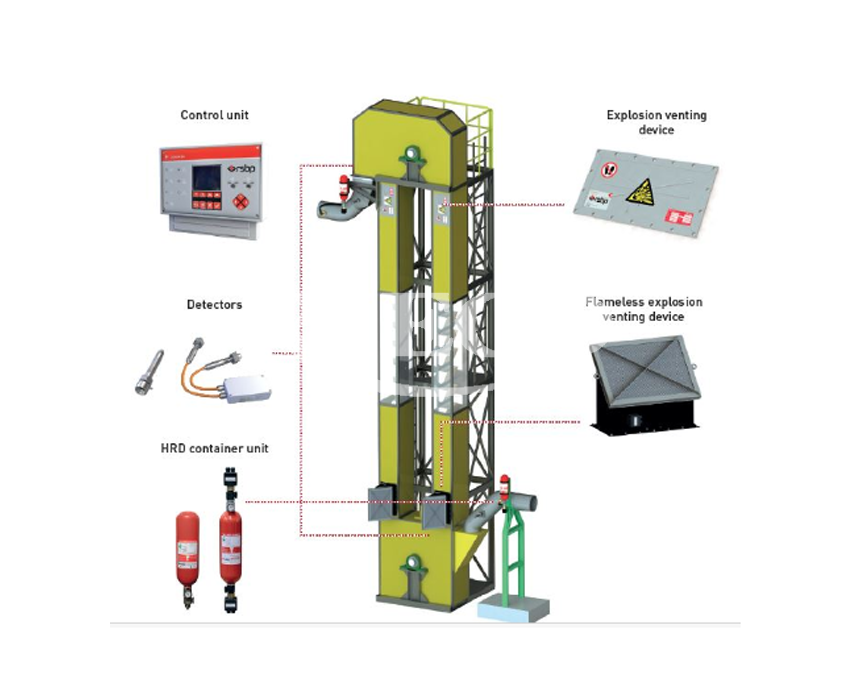

ELEVEX - Explosion Protection of Bucket Elevators

ELEVEX is the effective solution of bulk material vertical transport explosion protection. ELEVEX reduces explosion pressure to an extremely low value, which means that even existing and used technologies can be safely protected in case of explosion completely without destructive effects. The list of factors that can cause an explosion in a bucket elevator or similar vertical transport system is long, and the probability that an explosion will occur during operation is high. Although the use of this system does not prevent the origination of an explosion in an elevator, the actual explosion effects can be brought to a minimum.

The most frequent initiation sources in bucket elevators are:

- Sparks caused by deviation of traction the system from its axis

- Sparks from the elevator drive or hot elevator surfaces caused by friction

- Glowing particles introduced together with transported material

- Bearing friction, etc

Spring loaded self-closing doors

Because of the combustion, high pressure wave produced in the Bag houses results in the explosion of the equipment & causes adverse effect by the destruction of the equipment & human life in the surrounding areas. Our spring-loaded door vents out the explosion pressure wave of the gases & safeguards the equipment & also surrounding human life. Since these doors have mechanical spring, the doors after venting out the high-pressure explosion waves come back to the original position.

Fire Protection Equipment

Unlike Explosion, the phenomenon of fire could spare you some time to take necessary action, but the loss happening due to fire will be huge. There are some processes where we cannot rule out the ignition and therefore there is the possibility or probability of fire. That is why industrial processes and equipment should undergo a thorough examination and professional evaluation.

Features

- Rapid Detection: Detects the initial phase of an explosion in milliseconds.

- Explosion Suppression: Suppresses flammable dust explosions to protect equipment and lives.

- Pressure Release Mechanisms: Includes rupture discs and explosion vents that activate at predetermined pressures to allow safe gas release.

- Redirection of Explosive Gases: Changes the direction of explosive gases, minimizing the impact.

- Explosion Isolation: Includes mechanical devices like B-FLAP I to prevent flame and pressure propagation between equipment.

- Vertical Transport Protection: ELEVEX system reduces explosion pressure in bulk material vertical transport.

- Spring-loaded Self-closing Doors: Vents high-pressure waves and reverts to the original position post-venting.

- One-time Use Devices: Some components, such as rupture discs, are designed for single use and require replacement after activation.

- Economical Solutions: Offers cost-effective protection against the propagation of explosions between pieces of equipment.

- Comprehensive Fire Protection: Ensures a professional evaluation of industrial processes to mitigate extensive fire damages.

- Protection Against Various Ignition Sources: Includes safeguards against sparks, glowing particles, bearing frictions, and more.

- Acid Mist

- Furnaces

- Autoclaves

- Gas absoption

- Building product mfg

- Incinators

- Blow tanks

- Kilns

- Boilers

- Lime hydrators/slakers

- Conveyors and transfer points

- Odor Control/removal

- Cupolas

- Crushers and screens

- Palletizing dissolving tank

- Vents rendering

- Dryers

- Sand system

- Fumes/VOC smelters

Why Rieco?

in your process challenges.

Industries We Cater

we are happy to answer