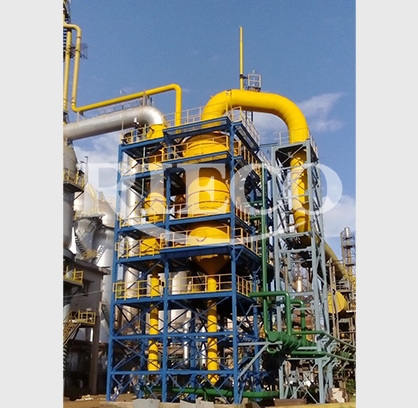

Cyclone Separator

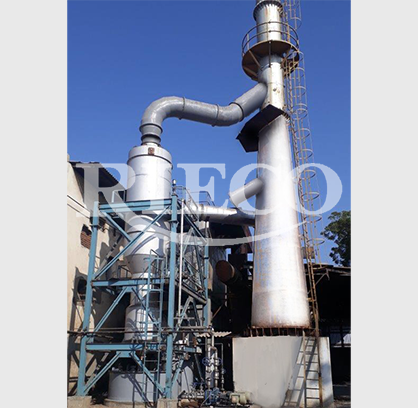

As experts in Air Pollution Control and particle separation technologies, our industrial cyclone separators effectively remove particulate matter via centrifugal force from air/gas streams, ensuring cleaner, safer industrial operations. As soon as the gas enters the separator, the cyclone design moves the particle towards outer wall, letting the clear gas exit with toxic particle collection at the bottom. In extensive cases, multi-cyclone configurations can also be utilised. With a blend of innovative design, engineering excellence backed by decades of expertise, and robust construction, our solutions deliver high-performance results tailored to your unique operational needs. Discover how our gas cyclone separator or cyclone dust separators can revolutionize your particle separation process and contribute to a cleaner environment.

Types of Cyclone

Cyclone dust separators come in various designs to meet the needs of different applications. Here are some of the most common types:

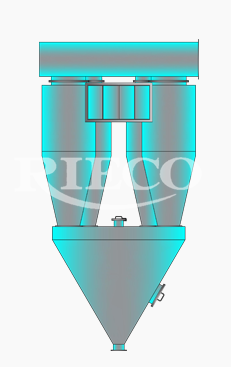

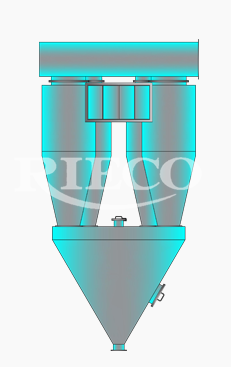

Inertial or Gravity Cyclones

These are the most common types of cyclones. They use a combination of rotational effects and gravity to separate dust and particles from the air stream. As the air spirals inside the cyclone, heavier particles are flung to the walls and fall to the bottom.

High-Efficiency Cyclones (HECs)

HECs are designed to remove smaller particles from air streams compared to gravity cyclones. They're often taller and have a smaller diameter, which creates a longer path and more time to separate particles.

Multiple Cyclones

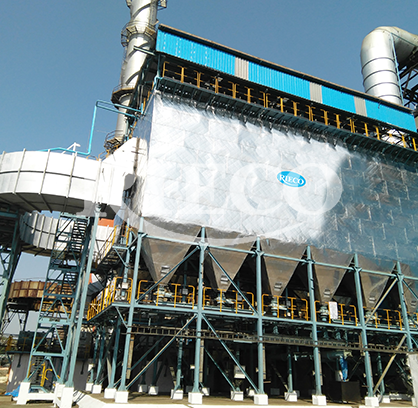

As the name suggests, it consist of a group of cyclone separators arranged in series or parallel. They're typically used in applications where high amounts of particulates need to be removed, or where several types of particles need to be separated.

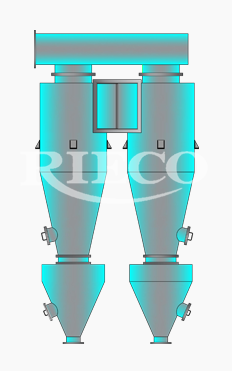

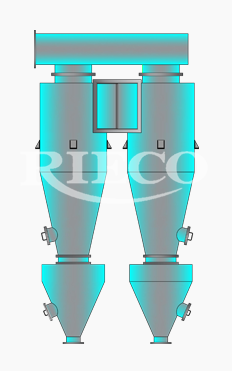

- Twin Cyclones: Twin cyclones consist of two cyclone separators arranged side by side. They're used to increase the processing capacity or to manage different sizes or types of particles simultaneously.

-

- Triple Cyclones: This setup includes three cyclone separators. They might be arranged in series or in parallel, depending on the application. Triple cyclones are especially useful in situations where there's a high volume of varied particulates.

- Quadruple Cyclones: As the name suggests, quadruple cyclones incorporate four cyclone separators. Quadruple systems are also versatile, allowing for the separation of multiple particle sizes and types simultaneously.

-

- Reverse-Flow Cyclones: These cyclones have a unique design where the inlet air enters from the top and the dust-laden gas flows downward into a spiral path. The dust particles are discharged at the bottom, while the clean air exits from the top.

Remember, the choice of cyclone type depends on the specific requirements of the application, including the size and type of particles to be removed, the volume of the air stream, and any specific environmental or operational conditions.

Cyclone separators come with a wide array of benefits that make them an ideal choice for various industries. Here are some key features:

- Efficient Particle Removal: Cyclones are capable of removing large to moderate-sized particles from the air, significantly improving air quality in industrial settings.

- High Dust Collection Efficiency: They offer superior dust collection efficiency, capturing a high percentage of particulate matter.

- No Filter Requirement: Unlike other dust collection systems, cyclones do not require filters, reducing ongoing maintenance and replacement costs.

- Simple and Trouble-Free Operation: Their uncomplicated design and lack of moving parts mean they operate smoothly with minimal interruptions or issues.

- Long-lasting Durability: Built for rugged use, they are designed to withstand tough operating conditions and have a long operational lifespan.

- Energy Efficiency: Their design and operation often make cyclone separators more energy-efficient than other air pollution control equipment.

- Adaptable to High Temperatures and Pressures: These separators can operate under high-temperature and high-pressure conditions, suitable for various industrial applications.

- Compact Design: Their compact nature ensures easy integration into existing processes, especially in spaces with constraints.

Why Rieco?

in your process challenges.

we are happy to answer