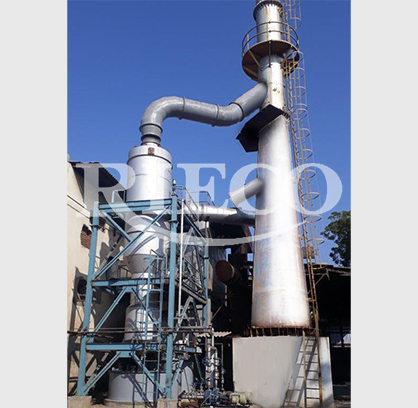

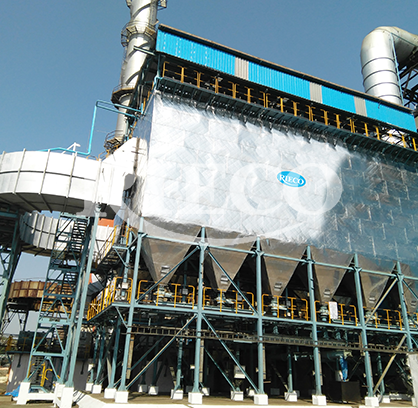

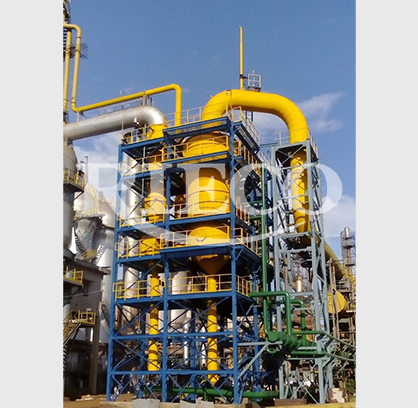

Cartridge Type Bag Filters

RIECO's Cartridge Type Bag Filters offer an innovative solution to dust separation and air pollution control in industries in case of space constraint. These compact filters, assembled in a pleated format, provide a greater filtration area than conventional filters, available in 45 or 60 pleat options and lengths up to 2.0 meters. These versatile filters are designed not only for dust separation but also to recover valuable products from the manufacturing process's air or gas flow. With the ability to handle volumes ranging from 100 m3/hr and above, RIECO's Cartridge Type Bag Filters provide an efficient, space-saving solution for diverse industrial requirements.

Types

- RIECO Cartridge Type Bag Filters can be tailored to fit specific needs, offering customization in terms of Pleated Format Filters, Length Variations, and Volume Capacity, ensuring they align seamlessly with diverse industrial applications:

Features

- Compact Design: Optimized for spaces with height and footprint constraints.

- Pleated Format: Increases the filtration surface area, available in 45 or 60 pleat variations.

- Adjustable Length: Variants available up to 2.0 meters to cater to different spatial needs.

- Volume Flexibility: Capable of handling airflow volumes from 100 m3/hr upwards, suitable for diverse industrial processes.

- Dry Separation: Efficient in separating dust particles and facilitating product recovery from air streams.

- Material (MOC) Options: Available in both Mild Steel (MS) and Stainless Steel (SS), catering to varying industrial needs and environments.

- Customizability: Can be tailored based on pleat format, length, and volume capacity requirements.

Why Rieco?

As your global partner, we fully immerse ourselves

in your process challenges.

in your process challenges.

48 +

Years of Experience

40 +

Countries

6000 +

Successful Installations

300 +

Strong Team

5 +

Global Partnerships

3

Manufacturing Facilities

Global Presence

We’re there for you

Feel free to ask us anything you have in mind,

we are happy to answer

we are happy to answer

Enquire Now

Close

Enquire Now

Warning: include(../../../includes/enquire-now.php): Failed to open stream: No such file or directory in /home/u466608992/domains/rieco.com/public_html/solutions/air-pollution-control/cartridge-type-bag-filters.php on line 246

Warning: include(): Failed opening '../../../includes/enquire-now.php' for inclusion (include_path='.:/opt/alt/php81/usr/share/pear:/opt/alt/php81/usr/share/php:/usr/share/pear:/usr/share/php') in /home/u466608992/domains/rieco.com/public_html/solutions/air-pollution-control/cartridge-type-bag-filters.php on line 246