Bag Filter

Protecting your workspace from airborne contaminants is more than just a health and safety measure—it's a commitment to the well-being of your employees and the efficiency of your operations.

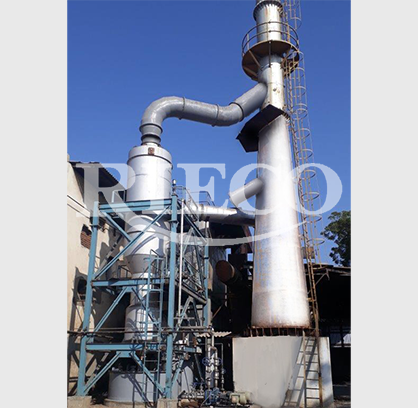

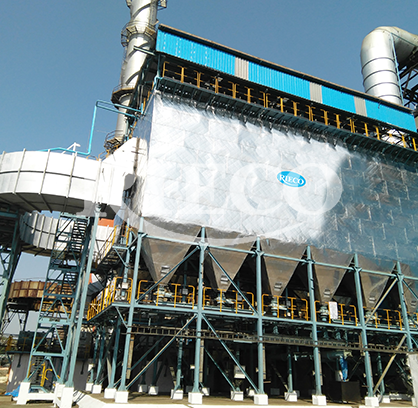

Our bag filters, also known as fabric filters or baghouses, play vital role in achieving this safety standard by dust extraction mechanism. Typically installed on material handling systems or at production process vents, these dust collection systems reduce emissions within work zones and through exhaust avenues, promoting a healthier workplace.

Our bag filters, designed for dust extraction and product recovery, are tailored to any flow rate. Enhanced with electronic controls and versatile design options, we create the ideal filtration solution for your specific needs.

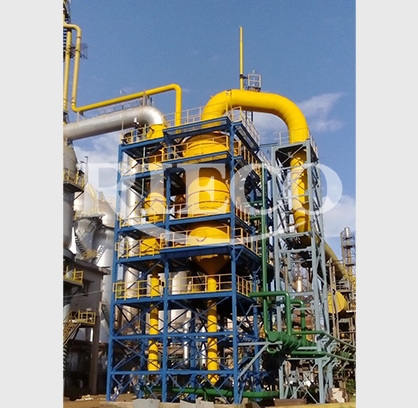

Our advanced bag filter technology adeptly prohibits dust emission in multiple industries. Through various types of baghouse filters, such as shaker baghouse,Through our pulse jet baghouse and reverse air baghouse we satisfactorily capture particulates from the gas stream. Owning to the high-performance of industrial pleated filter bags, we also ensures that bags are cleaned for the optimal performance.

Especially in highly pollution creating industries like steel, cement, minerals, mining, etc. utilizing compressed air for retaining productivity is vital. Taking cleaning cycle into account for preserving air quality is a must, and thus, our baghouse dust collectors come into play for stockpiling dust as a part of cleaning method, expanding equipment’s lifespan.

Types

Based on design, shape, and cleaning mechanism, there are the following types of pulse jet bag filter dust collectors available, each based on particular usage application. These collectors act as control devices that completely remove particulate from dust-laden air, enabling a cleaner and safer workplace.

- Top Entry Pulse Jet Filter: Air enters from the top, dust settles at the bottom.

- Bottom Entry Pulse Jet Filter: Air enters from the bottom and exits clean from the top.

- Top Removal Pulse Jet Filter: Enables top access for filter bag and cage removal.

- Side Removal Pulse Jet Filter: Allows side access for filter bag and cage removal.

- Modular Pulse Jet Filter: Designed with expandable modules for increased filtration area.

- Long Bag Pulse Jet Filter: Features longer bags for a larger filtration area within a smaller footprint.

- Cylindrical Pulse Jet Filters: Utilizes a cylindrical design for efficient air distribution.

- Rectangular Pulse Jet Filters: Uses a rectangular shape for suitable fit in specific spatial constraints.

- Online Cleaning Pulse Jet Filters: Offers continuous operation with simultaneous filter cleaning.

- Offline Cleaning Pulse Jet Filters: Provides thorough, section-wise cleaning without interrupting overall operation.

Features

- German Reverse Air Pulse Jet Filtration: Our filters utilize pioneer German technology for efficient pulsing of filter bags.

- Opti-Air™ Pulsing System: Our system employs the "On-demand" pulsing technology of Opti-Air™ for optimal use of pulsing air. This ensures the DP remains within limit and proper suction level at the source point is maintained.

- Advanced Performance Optimization: We harness cutting-edge Computational Fluid Dynamics (CFD) simulations to refine the performance of our bag filter systems.

- Experienced Handling of Various Filter Media: Our rich experience of 45+ years across diverse industries enables us to proficiently handle various types of filter media.

- Superior Quality In-House Cage Manufacturing: Our fully automated facility guarantees top-tier quality of cages, ensuring precision in areas like concentricity, weld quality, wire straightness, and fitting of collars & venturis.

- State-of-the-Art Rotary Air Lock Valve Production Facility: Our sophisticated machining facility at Alandi produces high-quality components of rotary air lock valves, a critical part of any bag filter. We oversee the machining of rotors/housing, shafts, assembly & testing, ensuring optimal overall performance.

- ACGIH Norms Compliant Engineering: We design our dust extraction systems according to the guidelines set in the latest edition of ACGIH.

- On-Site System Studies: We conduct on-site system studies for critical applications and situations with process challenges, ensuring your filtration system meets its specific requirements.

- Superior Emission Control: Maintain work zone emissions as low as 1-2 mg/Nm^3, ensuring cleaner air even just 1 m away from the source.

- Modular Design: The Bag Filter consists of three primary sections: Plenum, Housing/Casing, and Hopper, allowing for easy assembly and maintenance.

- Advanced Filtration: Equipped to sieve out even submicron-sized particles, ensuring clean air quality.

- Baffle Plate Protection: Designed to protect filter bags from direct dusty gas impact, resulting in the settlement of heavier particles in the hopper.

- Self-cleaning: The built-in cleaning mechanism ensures that dust accumulation on the filter bags is regularly cleared, maintaining consistent filtration efficiency.

- Optimized Utility Consumption: Designed for minimal utility requirements, maximizing efficiency.

- Durable Construction: Made to withstand various industrial environments and demands, extending the system's longevity.

- Customizable Ductwork: Suction hoods and dampers can be tailored based on specific needs, ensuring efficient dust capture.

Our bag filter dust collectors are extraordinary specimens of cutting-edge solutions for dust collecting. To know the latest price or professional advice for any dust collector requirements, get in touch with us.

Why Rieco?

in your process challenges.

we are happy to answer