- Industries

- Solutions

- Products

- Our Company

- Knowledge

- Contact Us

The Science of Air Movement: Mastering Fan Selection, Performance and Installation (Part3)

Fans serve a critical function in industrial operations, but choosing and maintaining the right fan for your needs can be a challenging undertaking. This blog aims to address this challenge by discussing the importance of factors such as selection of fan based on fan curves, actual versus desired performance of fans, fan laws, and installation techniques, all of which are vital for optimizing the performance and efficiency of your industrial fans. By following these guidelines, you can achieve improved operations and reduced costs, all while ensuring the effective operation of your industrial fans.

There are several reasons why the system design, fan selection, fabrication, and installation process can result in operation at some point other than design. The “Fan Laws” are useful when changes of fan performance are required.

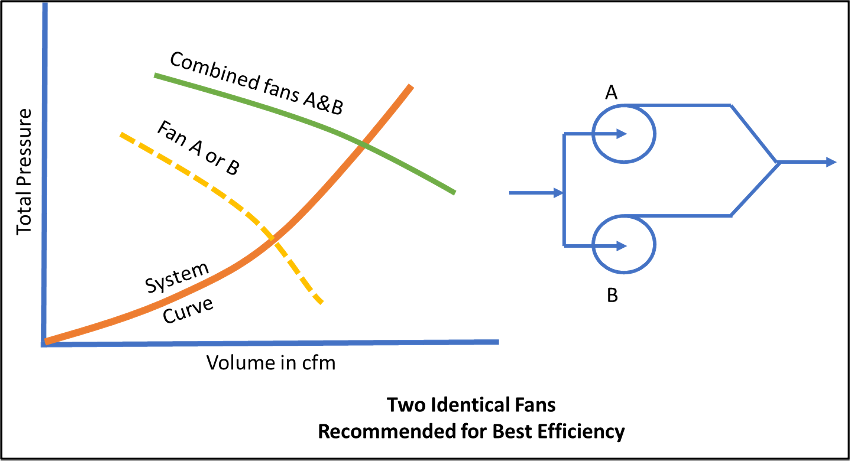

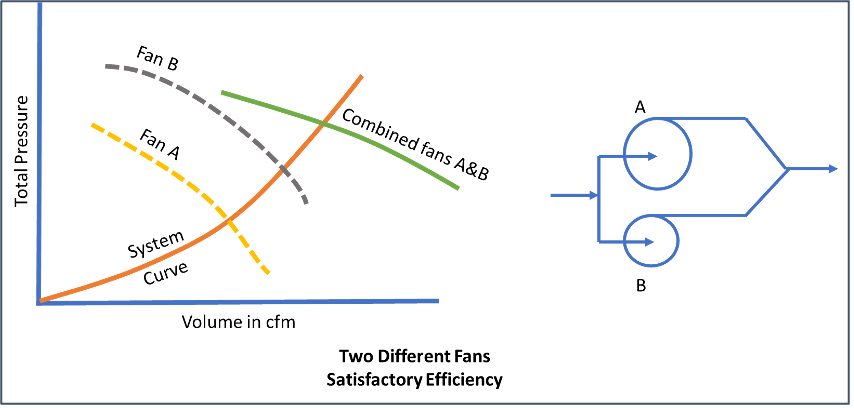

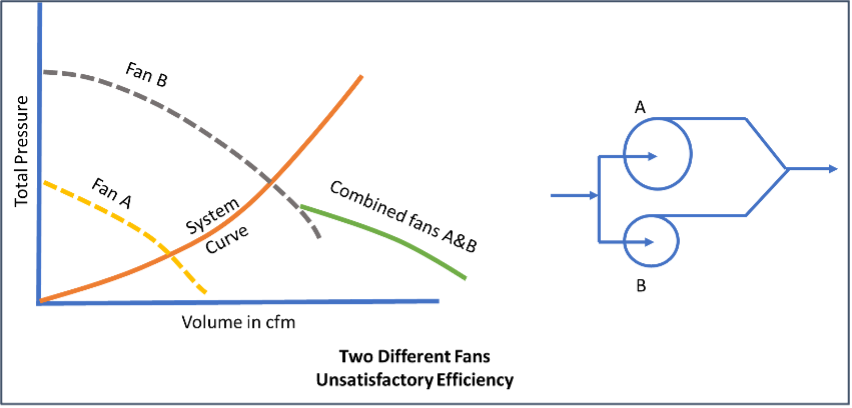

Figure depicts the four general conditions which can result from the system design fan selection process.

Fan laws are governing principles useful for determining requirements where change in output of the fan is required for a given system. At the given changed speed of the fan, the new operating point will be determined by following fan laws-

- Flow rate is directly proportional to Fan Speed

- Pressure is directly proportional to square of Fan Speed

- HP is directly proportional to cube of Fan Speed

Fan rating tests for flow rate, static pressure, and power requirements are conducted under ideal conditions which include uniform straight air flow at the fan inlet and outlet. However, if in practice duct connections to the fan cause non-uniform air flow, fan performance and operating efficiency will be affected. Location and installation of the fan must consider the location of these duct components to minimize losses. If adverse connections must be used, appropriate compensation must be made in the system calculations. Once the system is installed and operating, routine inspection and maintenance will be required if the system is to continue to operate at original design levels.

In conclusion, mastering the science of air movement is a critical aspect of achieving optimal industrial operations. By selecting the right fan, understanding its performance characteristics, and installing it correctly, you can harness the power of air movement to enhance productivity, minimize downtime, and create a comfortable and safe work environment. The desired performance of the fan should be compared with the actual performance to ensure that it is working correctly. Furthermore, fan installation can be done in series or parallel configurations to help achieve the desired performance. With the right knowledge and resources, you can become a master of air movement, taking your industrial operations to new heights of efficiency and productivity.

We at Rieco have 1000+ installations of various types of industrial fans in wide variety of applications in various industries like steel, cement, food, minerals, power, oil, and gas, etc. To select the most efficient fan for your application, write to us at rieco@rieco.com.